Author: Site Editor Publish Time: 2025-10-29 Origin: Site

As the core medium for transmitting electrical energy within electronic and power systems, electrical wires function as the "blood vessels" of the entire system, supporting the normal operation of various scenarios such as industrial production, building power supply, and electronic equipment operation. From household lighting circuits to power transmission in large factories, from internal wiring in precision electronic instruments to long-distance power transmission, the performance of wires directly determines the stability and safety of the entire system.

Among the many types of wires, stranded wire and solid wire are the two most widely used. They exhibit significant differences in structure, performance, and suitable applications. Therefore, thoroughly grasping the characteristics of solid and stranded wires is a fundamental prerequisite for ensuring the efficient and safe operation of electrical systems.

Solid copper wire features a simple structure, consisting of a single, continuous copper conductor core without stranded design.

The solid copper wire's conductor is a single, unbroken copper core with no gaps. This results in lower resistance, greater stability during power transmission, reduced voltage drop, and decreased energy loss.

In manufacturing, its simple structure eliminates the need for complex stranding processes, leading to higher production efficiency and relatively lower costs, offering a price advantage.

Their superior transmission performance makes them suitable for long-distance power or signal transmission, with significantly lower signal attenuation than stranded wires, ensuring transmission quality over extended distances.

Additionally, the single-core structure ensures tighter contact with terminals or connectors, providing greater connection stability and reducing issues like loosening.

Constrained by its single-strand structure, solid copper wire exhibits high rigidity and limited flexibility. It is difficult to bend during installation, particularly in confined spaces or complex wiring environments, resulting in reduced maneuverability and operational challenges.

Solid copper wire is commonly used for fixed wiring within buildings, such as installations inside walls or conduits, where it maintains long-term stability.

In power distribution systems, solid copper wire is typically chosen for supply lines running from distribution boxes to individual outlets, ensuring reliable daily power supply in residential and commercial settings.

For long-distance power transmission scenarios, such as outdoor power transmission lines, solid copper wire effectively reduces energy loss and signal attenuation.

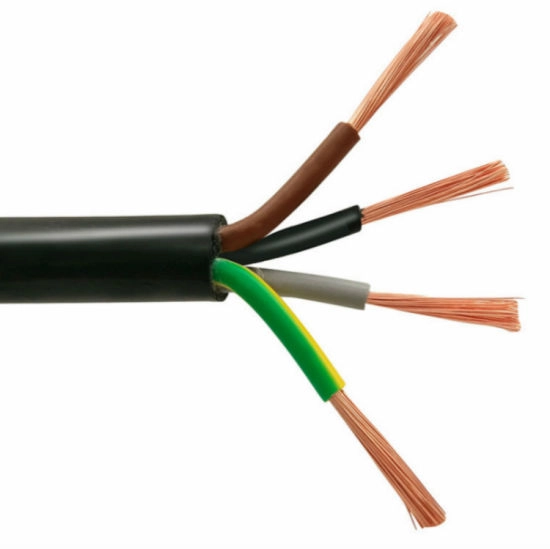

Stranded wire consists of multiple fine copper wires twisted together using specialized equipment to form a single conductor.

High flexibility is the most prominent advantage of stranded wire. It can withstand repeated bending and twisting without damage.

Stranded wire maintains excellent performance in environments with vibration or where equipment needs to be moved, resisting failures like breakage caused by vibration or movement.

Its flexible nature makes installation more convenient, particularly suitable for confined spaces and complex routing paths, easily adapting to various installation environments.

The gaps formed during the twisting of multiple copper strands result in slightly higher resistance compared to solid copper wire. This leads to slightly lower electrical transmission efficiency over long distances and relatively greater power loss.

The complex stranding process increases production difficulty and cost, making stranded wire more expensive than solid copper wire.

For mobile devices and cables subject to frequent plugging and unplugging, such as phone chargers and computer data cables, the high flexibility and bend resistance of stranded wire make it an ideal choice.

In environments like server rooms, twisted pair cables are commonly used for internal cabinet patch cords and network equipment connections, facilitating equipment maintenance and line adjustments.

In applications requiring frequent movement or subject to vibration, such as automotive systems, audio equipment, and portable power sources, twisted pair cables reliably maintain functionality, ensuring uninterrupted device operation.

Wires | Stranded Copper Wire | Solid Copper Wire |

Structure | Multiple fine copper wires twisted together to form a single conductor | Single copper core, no stranded design |

Flexibility | Significantly superior to solid copper wire, withstands repeated bending | Poor, high rigidity, difficult to bend |

Conductivity | Slightly higher resistance, relatively larger voltage drop, and marginally lower transmission efficiency | Lower resistance, smaller voltage drop, higher transmission efficiency |

Cost | Higher cost, complex stranding process, greater production difficulty | More cost-effective, simpler manufacturing process, higher production efficiency |

Installation Difficulty | Easier to handle in complex environments, high installation flexibility | Challenging to operate in complex environments, limited flexibility |

Connection Stability | Strands tend to separate during terminal connection, requiring additional securing/crimping | Tight contact during terminal connection, higher stability |

Application Scenarios | Suitable for dynamic scenarios involving frequent movement, bending, and vibration, such as appliance power cords, mobile device cables, cabinet patch cords, and automotive internal wiring | Preferred for fixed, long-distance, high-power applications such as building wiring, long-distance power transmission, and high-power fixed equipment power supply |

Solid Copper Wire: Suitable for fixed installations requiring no frequent movement or bending, such as building wall wiring and long-distance power transmission lines.

Stranded Wire: Ideal for environments involving frequent bending, movement, or vibration, such as appliance power cords, mobile device cables, and automotive internal wiring.

Select the appropriate wire gauge based on the maximum current demand of the electrical equipment. A larger gauge wire has a higher rated current capacity. Simultaneously, verify the wire's rated voltage parameters to ensure it meets the system's voltage requirements.

Solid copper wire: For longer routing distances to minimize voltage drop and power loss

Stranded wire: For shorter routing distances where voltage drop and power loss are less critical, and flexible installation is required

Environmental factors like humidity, temperature, and corrosiveness impact wire lifespan. For high-temperature environments, consider A-Line's high-temperature wires rated up to 105°C. In damp or corrosive settings, select wires with moisture-resistant and corrosion-resistant insulation materials.

Stranded wire and solid wire exhibit distinct differences in structure, performance, and suitability.

Solid wires offer low resistance, stable transmission, and lower cost, making them ideal for long-distance, fixed installations.

Stranded wires provide high flexibility and installation ease, suitable for frequent movement and complex wiring scenarios.

As a professional wire and cable manufacturer, A-Line Cable offers different electrical wires that fully consider diverse user needs. Customization services are available, providing both stranded wire and solid wire options. The conductor utilizes either bare stranded copper or solid copper, with both insulation and outer sheath made of PVC. Rated voltages cover 300/500V or 450/750V, while rated temperatures offer multiple options including 70°C, 90°C, and 105°C, ensuring adaptability to diverse high-temperature environments. Certified under ISO9001, CE, CCC, RoHS, and other standards, the product guarantees quality while featuring fireproof properties. It meets electrical demands across construction, appliances, electronics, and more. A-Line Cable accommodates small-order purchases and provides OEM services. With premium products, competitive pricing, and comprehensive after-sales support, it enjoys a strong global reputation.

Contact A-Line Cable! Whether you choose stranded wire or solid wire, we provide reliable product solutions to ensure the stable and safe operation of your electrical systems.

Originated Cable & Wire business in 1998, We has been dedicating itself to the manufacturing and exporting of high-quality Cable Assemblies, Wire Harnesses for lighting & Home Appliances, Worldwide Power Cord, Indoor & Outdoor Extension Cord, Electrical Wires, Plug Inserts or custom-made products.